Cad / Resin Casting

Using Docs with Cad technology and models

Making Casting Easier, Faster for Twenty Years

About Those Printed Models

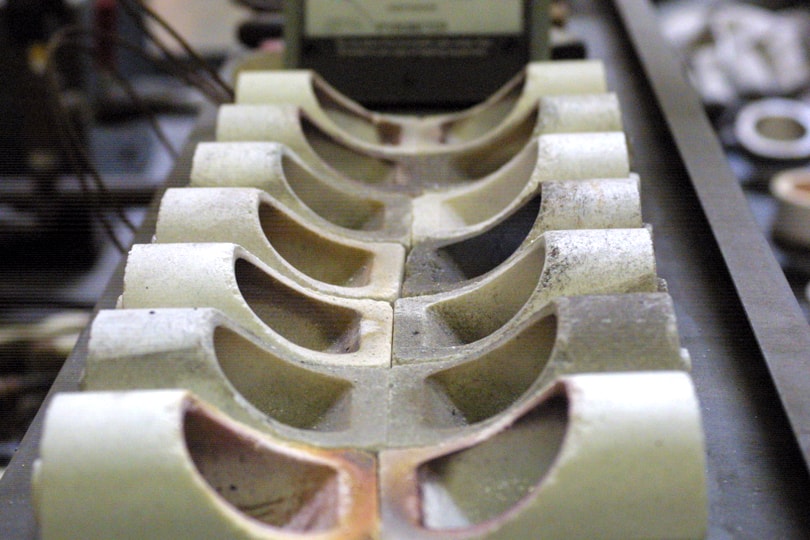

The material used in the actual rapid prototype process makes all the difference. The most difficult Cad models are essentially a high technology resin, cured by light. One disturbing quirk is a lack of curing in UV light makes a good casting far less likely. They come in seemingly endless types each with its own advantages, perhaps its own disadvantages.

For all of these you will need to use a very hot and relatively long burnout, 1600 Degrees Fahrenheit, at 8 hours, Doc’s has the extraordinary strength to withstand the natural expansion inherent to these models before they soften and burn out.

Cad designs by nature often have some of the most difficult details, negative spaces and “choke points” for metal flow difficulties. Doc’s has the best chance to withstand the impact of molten metal flowing into thin places like small holes in the design. Doc’s is the investment of choice for designs with deep lettering.

Casting Temperature table

These are estimates based on general purpose casting.

Platinum 100-600F

950 Palladium 1000-1150F

Nickel white gold 1000-1150F

Palladium White gold 1000-1150F

Yellow Gold 850-1100F

Our Mission

No matter what or how you cast we are here to help. Our support is aimed at you and your shop not just our casting plaster.